|

상세 정보 |

|||

| 건조한 방법: | 전자 레인지 | 먹이주기: | 0.75kW |

|---|---|---|---|

| 생산 속도: | 15-25m/분 | 운행 방향: | 왼쪽에서 오른쪽으로 |

| 주파수 브랜드: | 실린 또는 슈나이더 | 플레이트 유형: | 그라비아 플레이트 |

| 되감기 접기 오류: | ± 0.1mm | 전달 방향: | 왼쪽에서 오른쪽으로 |

| 강조하다: | 산업용 소파 건조기,달걀 트레이에 맞춤형 마이크로파 터널 시스템,식품 포장용 전자파 진공 건조장비 |

||

제품 설명

펄스 폼딩용 산업용 마이크로 웨브 건조 기계 - 달걀 트레이 및 식품 포장용 사용자 정의 가능한 터널 시스템

제품 설명:

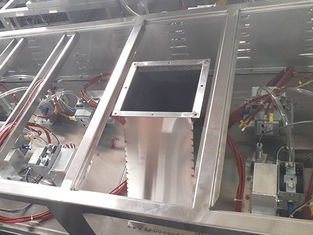

이 산업용 마이크로파 건조기는 펄스 폼프 산업을 위해 특별히 설계되었습니다.과일 트레이물 분자를 직접 가열함으로써 건조 시간을 몇 시간에서 몇 분으로 크게 줄이고,더 낮은 에너지 소비를 가진 더 높은 품질의 최종 제품전체 생산 라인은맞춤형당신의 출력과 공장 레이아웃에 맞게

생산 라인의 구성:

-

공급 컨베이어 (형조 기계와 동기화)

-

마이크로웨이브 난방 (마그네트론 배열과 함께)

-

뜨거운 공기의 순환 시스템 (습기 배출을 위해)

-

배기 및 탈습 시스템

-

출수 및 냉각 컨베이어

-

터치 스크린 HMI와 PLC 제어 캐비닛

-

컨베이어 속도 조절용 변주 주파수 드라이브 (VFD)

기술 매개 변수:

| 매개 변수 | 세부 사항 |

|---|---|

| 모델 | MWT-PM 시리즈 (완전)사용자 정의) |

| 전력 출력 | 30kW, 50kW, 80kW, 100kW (선택 &사용자 정의) |

| 입력 전압 | 380V/415V 50Hz/60Hz 3단계 (또는맞춤형) |

| 건조 온도 범위 | 70°C - 120°C (정밀 조절) |

| 컨베이어 벨트 너비 | 600mm, 800mm, 1000mm (사용자 정의) |

| 건조 시간 | 5~15분 (VFD를 통해 조절) |

| 제어 시스템 | PLC + 터치 화면 HMI (프로그램 가능한 요리법) |

| 전체 차원 | 맞춤형전력 및 구성을 기준으로 |

적용:

계란 트레이, 과일 트레이, 산업용 포장, 종이 냄비 심채 및 기타 3D 형성 섬유 제품을 건조하기 위한 펄프 폼 업계

사용자 정의:

우리는 광범위한사용자 정의터널 길이, 벨트 종류와 너비, 전력 구성, 제어 시스템 통합, 그리고 전체 레이아웃을 포함해서

특징:

-

빨리 그리고 단위로내부에서 바깥으로 가열하는 것입니다.

-

최대 40%의 에너지 절감기존의 오븐과 비교하면

-

완전히 사용자 정의각기 다른 제품의 전력과 컨베이어 속도

-

제품 강도를 높이고 깨지는 것을 줄입니다.

-

콤팩트한 디자인으로 값비싼 공장 공간을 절약할 수 있습니다.

-

PLC 컨트롤은 일관성 있고 반복 가능한 결과를 보장합니다.

지원 및 서비스:

우리는 설치 감독, 운영자 교육, 원격 기술 지원, 그리고 쉽게 사용할 수 있는 예비 부품 공급을 포함한 포괄적인 지원을 제공합니다.

포장 및 운송:

이 기계 는 안전 한 해상 화물 및 육상 운송 을 위해 수출 할 수 있는 나무 케이스 또는 철 프레임 에 안전하게 포장 되어 있다. 모든 부품 은 쉽게 식별 할 수 있도록 명확 히 표시 되어 있다.

FAQ:

-

Q: 이 기계가 제 자동 펄스 폼 머신과 연결될 수 있나요?

A: 네, 입력 및 출력 높이 및 속도는 완전히맞춤형원활한 통합을 위해 -

질문: 마이크로 웨브 건조 는 연약 한 펄프 구조 를 손상 시킬 것 인가?

A: 아니, 온도와 전력은 굽거나 변형되는 것을 방지하기 위해 정확하게 제어되어 더 일관성 있는 제품을 만듭니다. -

질문: 일반적인 납품 기간은 얼마입니까?

A: 납품 기간은사용자 정의보통 20~35일 정도입니다.